The ambition to make something perfect and to produce tools of excellent quality. This is what we mean when we say 'typically Festool'. And this is also typical of our region, full of world market leaders and hidden champions, where Swabian inventiveness, down-to-earthness and the highest quality awareness lead to unique products and services.

Our success story

We are proud of our 90-year company history. At the same time, we are a forward-looking company and are continuously evolving to meet the demands of a global future, which is bringing our world ever closer together.

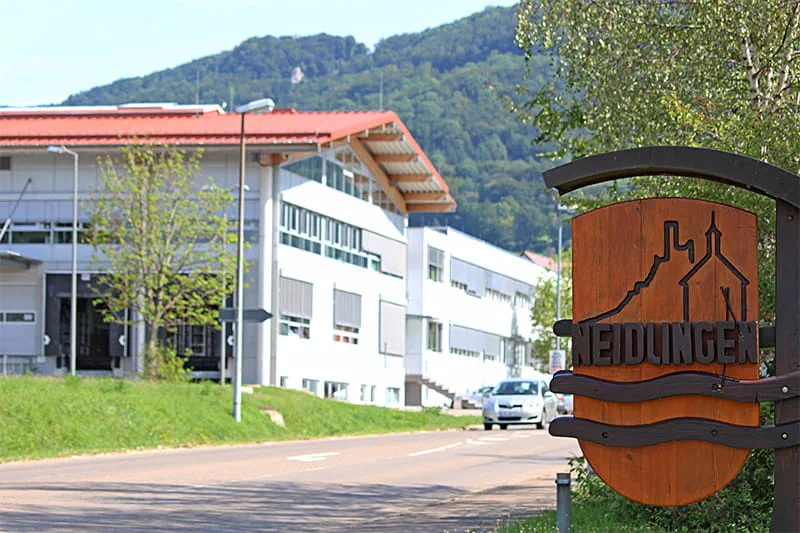

Our aim is to guarantee the same quality at all production locations, according to the "Made in Germany" standard. Each of our plants is specialised in the products that are produced there and works according to the quality standards developed in Neidlingen. This network of plants guarantees our high quality standard. We currently produce 80 percent of our products in Germany. High-volume products and products with small batch sizes are produced in Česká Lípa. Our plant in Česká Lípa works with the same processes and quality standards and is specialised in high-volume products, a task made easy by the generous space conditions at this location.

Our objective

"If it needs to be done right, then it is best to do it ourselves"

A sentence that gets to the heart of the matter. Our drive. Our objective. And above all: Our passion. And it was said by none other than our company founder Gottlieb Stoll. That was back in 1925. Over 90 years have passed since then – Festool can now look back on a unique success story with pioneering inventions and power tools. Our greatest passion lies in wanting to continuously improve products – and it's also our daily motivation. And we have always remained true to our principles.

Quality ...

The same applies to our power tools: In every development stage, our products are subjected to tough, week-long practical tests in our company's own testing laboratories and test stations. This allows us to find and eliminate even the smallest of weaknesses long before the series production stage – quality comes at a cost for a reason. It is also no coincidence that many Festool customers are still working with tools that they have already been using for over 30 years.

Innovation

We are passionate inventors and tinkerers, as shown by a glimpse into our history: In 1951, our orbital sander revolutionised surface finishing and became the global synonym for orbital sanders. In 1964, we impressed our users by combining a portable circular saw with a guide rail for the first time. 1976 was the year of dust-free working when the first eccentric sander with integrated extraction was brought to market. In 2006, this was followed by the sophisticated DOMINO jointing system – a unique solution for joining pieces of furniture together (see illustration). For years, we have been keeping workplaces and construction sites tidy with SYSTAINER. These are not the products of chance, but the result of many years of development work and the experience of our passionate employees. They significantly improve and simplify the daily work of our professional users. But there's always room for improvement, even in our best products, which are already considered classics in many workshops – such as our TS 55 plunge-cut saw.

A sprinter has a unique elasticity, a marathon runner amazing stamina and a shot-putter enormous power reserves. What they all have in common is the perfect preparation for their respective discipline. The EC-TEC drive concept, specially developed by Festool, works precisely according to this principle. Find out what exactly this means here:

System

SYSTAINER, power tools, mobile dust extractors: We bring together what belongs together – cleverly and uniquely. Under the motto "Systems get it done. Perfect in every way.", we develop our storage and organisation system meticulously – of course still with an uncompromising quality standard. Accessories, consumables and tools are perfectly co-ordinated with each other, down to the finest detail. This results in a streamlined work process for our users, which enables fast and productive work, prevents idle times and reduces the amount of reworking.